Crumar Performer

Repair Pics

|

| As far as I can tell, what started the ball rolling was the screw from this hole in the front panel coming loose (it was found inside the packaging). The whole unit was then vulnerable to racking, and as you can see here the edge of the front panel scraped back and forth against the black keys in-transit. |

|

| Crack behind the power-supply. Not too bad this one, and I left as-is. |

|

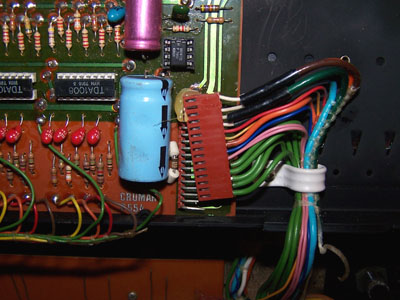

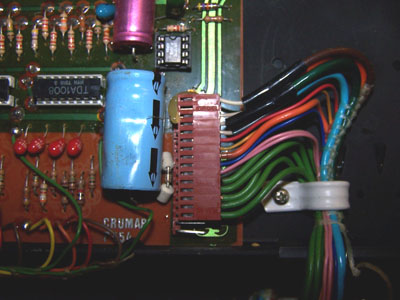

| A few of the connector plugs came a bit loose during shipping as well. It must've gone through one hell of a ride. |

|

| Easily straightened. |

|

| A screw from the front panel hinge was ripped right out here, taking a chunk of particle-board with it. |

|

| Some epoxy compound replaced the missing wood. |

|

| Another screw in the front-panel hinge came out here, but the wood remained. Three came loose in total from the back of the unit. |

|

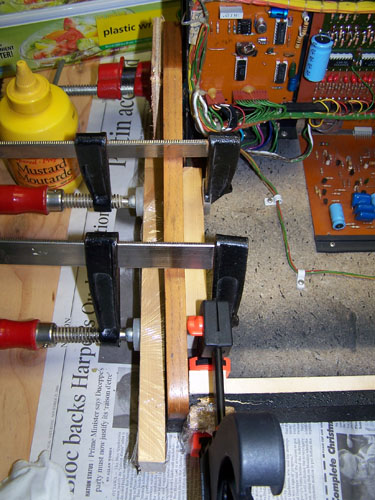

| A little wood glue, some clamps... |

|

| And it fixed-up nicely. I used pieces of toothpick and more glue to fix the stripped screw-holes. |

|

| The worst bit of damage occurred to the left end-cheek, as seen here. |

|

| Note the bend in the wood, which pushed against the keyboard movement - snapping the tabs off two keys. |

|

| Lots of wood-glue and some clamps straightened this out. |

|

| I clamped the lower corner at the same time; scroll down for more details. |

|

| Here you can see the two broken keys, and the shattered corner of the front casing. |

|

| More wood glue and clamping here. |

|

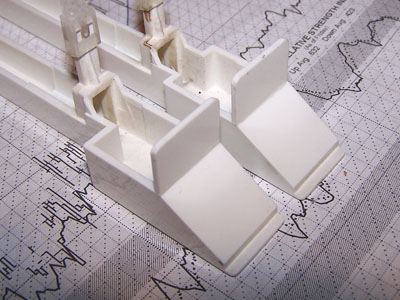

| And some epoxy on the keys. |

|

| Reinforcing plastic on the back of the tabs. |

|

| A healthy dose of filler compound, and the broken keys back in place. |

|

| When the end-cheek snapped, it forced this damping strip inward so it interfered with the keys. I was going to replace it, but further inspection showed it served no purpose. The keys don't actually make contact with it. |

|

| A closer look. |

|

| The damping strip removed. |

|

| And replaced with a much stronger 3/4" piece of pine; glued in place, and tacked along the front with three finishing nails. |

|

| I put screws through the end-cheeks into the reinforcing strip for extra strength. I found that the end-cheeks are made of slightly denser particle-board than the shockingly inferior front, back and base. |

|

| The slightly ugly, but much happier left end-cheek after repairs. |

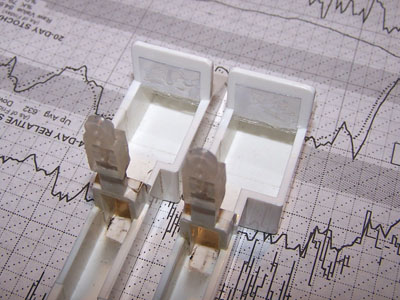

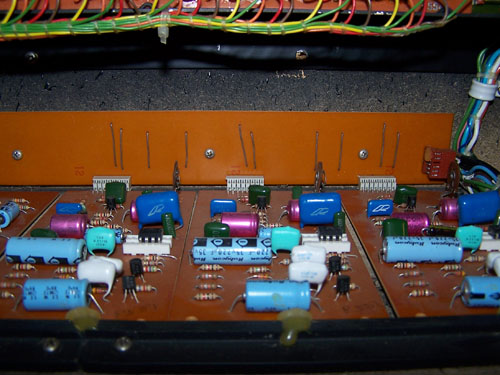

A couple of pics of the innards:

| Brass 1 | I was surprised at how much more than simple brass you can get out of this with some modulation. |

| Brass 2 | I was just messing about when I recorded these - some fun with the LFO. |

| Strings 1 | Ah... lovely. Quite a bit of modulation on this. |

| Strings 2 | A little less modulation. |

| Strings 3 | Some onboard EQ, and shorter envelopes. |